Why the rotational molding process?

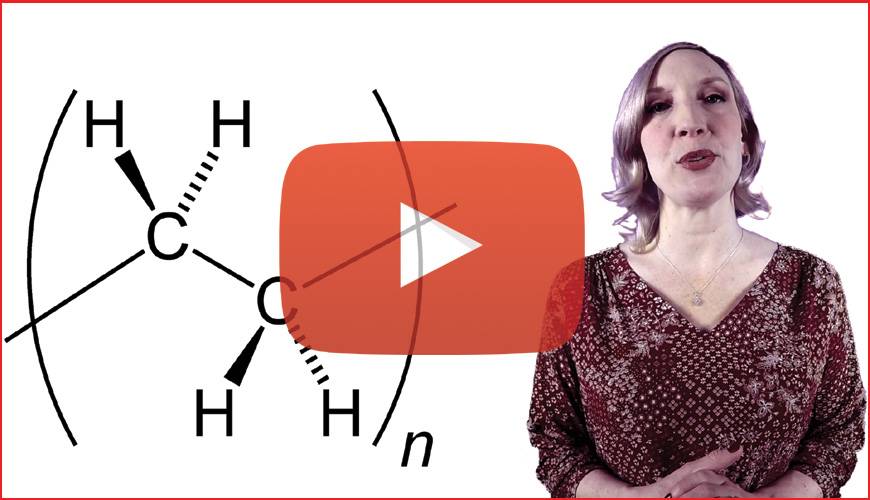

Rotational molding has several distinct advantages yielded by this manufacturing process. Polyethylene, the material used most for rotational molding contributes greatly to the durability of rotationally molded parts.

What are some qualities of rotationally molded polyethylene parts?

They last a very long time – materials for Rotational Molding last an extremely long time before they begin to biodegrade. The most commonly utilized material, Polyethylene has a half-life of 10,000 years. Rotationally molded parts will last much longer than other materials.

Polyethylene can be exposed to the elements - Able to withstand a wide range of temperatures in various environments and applications. Exposure to Water does not deteriorate the material. Rotationally molded parts can be buried in the ground or remain outside in the elements with little to no deterioration.

Rotational molding has the ability to manufacture parts with a double wall - A double wall part allows for structure to be added to maximize the performance and lifespan of a part. This double wall construction can often be filled with foam to add rigidity and strength. This creates parts and products that can perform for long periods of time under many stressful conditions. Custom Rotational Molding capabilities can produce products for virtually any application.

Rotationally molded parts are much lighter weight than many common materials, while remaining more durable and longer lasting.

Rotationally molded products can be made to meet the FDA requirements for food grade materials. Polyethylene is safe and non-toxic and can be used for storing food and drinking water.

Polyethylene can be exposed to a large number of chemicals without deterioration making rotationally molded parts especially effective for tanks used for manufacturing, agriculture, or housing toxic or caustic chemicals.

In summary, rotationally molded parts are long lasting, impervious to the elements, able to be manufactured with extremely durable double wall construction, light weight, safe for food and water and able to withstand a large number of toxic chemicals. Do any of your products need to do any of that? Then the rotational molding process might be right for you!